Bed rebar machine

Producing rebar with consistent and standard quality requires precise industrial equipment. In this article, you will learn about the challenges of traditional production, the principled solutions, and the specifications of the rebar machine, and you will read the criteria for selecting a reliable production line.

; an industrial solution to improve the quality and sustainability of production in the construction industry

Introduction

In recent years, the construction industry and related materials production have faced a series of simultaneous challenges; from severe fluctuations in raw material prices to a shortage of skilled labor, increased sensitivity of construction standards, and finally the instability of digital and Internet infrastructures, which has even directly affected industrial marketing and sales processes. In such circumstances, manufacturers who still rely on traditional or semi-industrial methods are faced with a decline in quality, reduced productivity, and loss of market trust more than ever before.

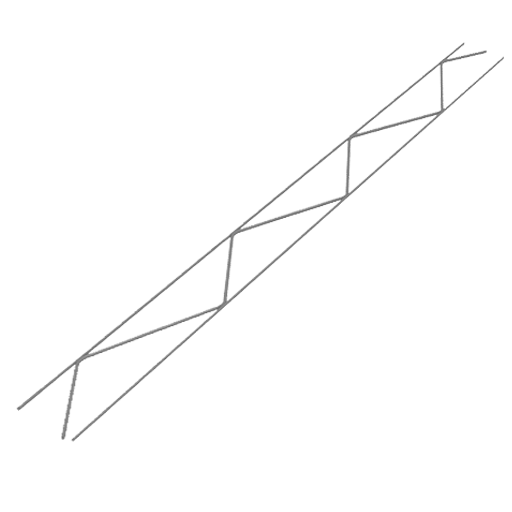

One of the key products in the modern construction chain is the bed rebar; an element that plays an important role in increasing the strength of masonry walls and improving structural performance. Sustainable and standard production of this product is practically not possible without the use of precise and automatic industrial equipment. This article attempts to examine the issue of bed rebar production from an analytical and industrial perspective and to explain its principled solution, namely the use of an industrial bed rebar machine, especially the solution provided by the Pars Baft Golestan Knowledge-Based Machinery Complex, in a specialized manner.

Investigating the main problem or need in the bed rebar production industry

The increasing use of non-load-bearing walls, lightweight blocks, and new building materials has highlighted the need for structural reinforcement in these areas more than ever before. The bed rebar, as a horizontal reinforcement, is responsible for distributing stress, preventing cracking, and increasing the integrity of the wall. However, the production of this product is associated with several technical challenges.

The first challenge is quality consistency. The smallest error in wire spacing, weld quality, or rebar diameter can affect the final performance of the bed rebar. The second issue is production capacity; many workshops are unable to meet the large orders of construction projects. The third challenge is hidden costs; rework, high waste, and frequent production line stops severely reduce profitability.

In addition to these factors, the requirement to comply with national and project standards has forced manufacturers to use controllable and repeatable methods. This is where the gap between traditional production and the real market need becomes completely apparent.

Traditional or non-industrial methods and their disadvantages

In many small units, the production of bed rebar is still carried out manually or semi-manually. In these methods, wire cutting, spacing adjustment and even welding depend on human labor. This dependence is itself a major source of error.

The most important limitations of these methods include the lack of quality stability. Production output is not the same in different shifts or by different operators. Also, the production speed is low and there is no possibility of precise planning for order delivery. Hidden costs are also significant; high energy consumption, tool depreciation, and increased waste ultimately increase the final price of the product.

Another important point is the reduction in competitiveness. In a market where construction projects are looking for reliable and regular suppliers, a manufacturer who cannot guarantee quality and delivery time is gradually eliminated from the supply chain.

Industrial and standard solution

The fundamental solution to overcome these challenges is to move towards industrial and mechanized production. The use of specialized rebar production machines allows for precise control of production parameters. In this approach, processes such as wire straightening, cutting, spot or resistance welding, and final shaping are carried out in an integrated and automatic manner.

Criteria for selecting a suitable industrial solution include performance accuracy, stability in continuous production, energy efficiency, and adaptability to diverse market needs. In addition, access to technical services and long-term support play a decisive role in the success of the investment.

Introducing the Pars Baft Golestan bed rebar machine

Pars Baft Golestan Knowledge-Based Machinery Complex, relying on practical experience in the wire and metal mesh industry, has designed and manufactured the bed rebar machine as a local and reliable industrial solution. This machine is engineered to meet the needs of medium and large production units.

The main role of this machine is to eliminate human error and ensure consistency in the quality of the final product. High automation, precision in adjusting the distances and uniform quality of the welds, make the produced bed rebar fully compliant with the requirements of construction projects. On the other hand, the robust industrial design and the use of durable components allow for continuous operation in long shifts.

The real competitive advantage of this machine is not simply in production speed; it is a combination of precision, durability, customization capabilities, and in-country technical support that minimizes the risk of production line downtime.

Important technical specifications and factors affecting device selection

When choosing a rebar machine, it is essential to pay attention to several key technical characteristics. Production capacity is the first determining factor; the machine must be able to meet the volume of current and future orders. Energy consumption is also of great importance, because in continuous production, small differences can lead to significant costs.

The accuracy and quality of the output, including wire spacing uniformity and weld strength, directly affects the product's market acceptance. Also, customization capabilities, such as the ability to produce bed rebar in different dimensions and specifications, allow the manufacturer to expand its customer base.

The machines designed by Pars Baft Golestan, taking these factors into account, provide the operator with the ability to adjust various production parameters and create high flexibility.

Important points before purchasing and setting up

Before purchasing a rebar bed machine, it is essential to consider the space required for installation and operation. Proper layout of the production line, easy access to raw materials, and product exit path increase productivity. In terms of manpower, although automatic machines reduce dependence on labor, the presence of a trained operator is required for monitoring and maintenance.

After-sales service and access to spare parts are among the most important criteria for selecting a supplier. In a situation where importing foreign equipment is associated with numerous restrictions and delays, working with a local and responsive manufacturer is a strategic advantage.

Conclusion

Producing quality and sustainable rebar is no longer an optional choice; it has become a necessity for survival and growth in the competitive construction industry market. Traditional methods, despite lower initial costs, in the long run lead to a decline in quality, increased costs, and loss of customer trust.

Moving towards the use of industrial bed rebar machines, especially the indigenous and engineered solutions of Pars Baft Golestan Complex, provides the possibility of quality control, increased productivity and market development. It is suggested that industrial managers and decision-makers, to examine the specifications and capabilities in more detail, study the bed rebar machine product page on the official website of this complex and adapt it to the real needs of their production line. This approach will be an effective step towards smart and sustainable investment.

Summary and call to action ( CTA )

If you are looking for an advanced, cost-effective, and fully standardized machine for producing bed rebar , Pars Baft Golestan machine is your best choice.

Contact our experts now to receive a free consultation, learn about the current price of the bed rebar machine , and take a big step in improving your business.

Invitation for free consultation and price inquiry

Pars Baft Golestan Machine Manufacturing Complex is always ready to provide free consultation to help you in selecting and purchasing a rebar production machine . To receive a detailed inquiry on the price of a rebar press machine and more technical information, just contact us.

Experience a different experience of quality, innovation, and support with Pars Baft .

▎Sources and references

Bed rebar production machine from Pars Baft Golestan Machinery Complex

Other