Wire pulling machine

Pars Baft Golestan Company, with more than a decade of experience in research and production, was able to be the first designer and manufacturer of wire tensioning machine in Iran, and with a long history in providing these machines, it was able to be the best company in the production of this product in Iran and the world.

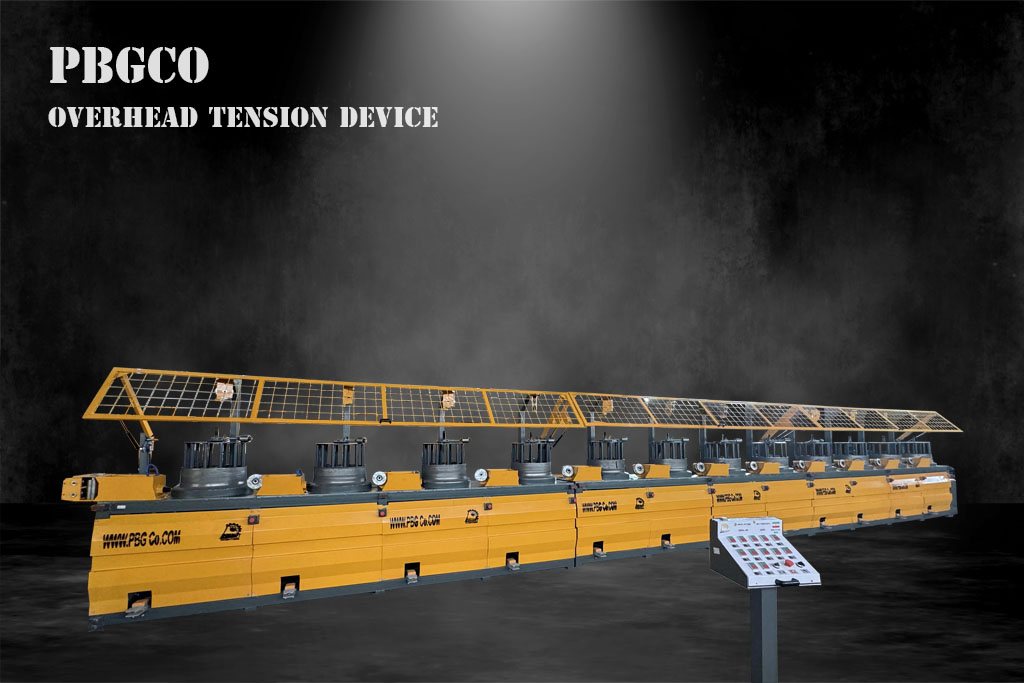

The wire tensioning machine made in Pars Baft company is divided into two types of direct tensioning and overhead tensioning, which according to the requested features, which include rotating doser, doser cooling system, air-cooled and water-cooled drum system, as well as production inverter system. It can be calculated according to the customer's request regarding the size of the input and the output size in terms of the number of drums needed.

Regarding direct or continuous tension devices, due to the reduction of tension during the wire tension, it causes no drastic changes in the hardness of the wire and increases the quality of the final wire, and it is more popular, but its price is slightly higher than Overhead samples. And according to the desired quality and easier operation and the satisfaction of the consumers of the final wire, this additional cost will be compensatory. Direct wire drawing devices have the ability to draw low carbon wires. It is also possible to cover high carbon wires if overhead devices are only able to stretch low carbon wires. This is an advantage designed on this device.

Direct tension works with plc and drive design, and for this reason, it also makes direct tension intelligent, and therefore it is considered a new generation of wire tension, which is very important and is of interest for products with low quality output.

But in overhead tensioning devices, due to the tensile and torsional stresses applied to the wire during size change, it is basically used in processes that require higher quality, but in order to use this wire for reinforcing wire, press netting, mesh netting, etc. There is no problem, by replaying, the tension on the wire can be reduced.

The most important features of this device are:

easy usage

Designed for

Three shifts

All the company's products have a 1-year warranty and 10-year after-sales service, along with free installation and training throughout the country.

General specifications

It has a PLC system

It has a strong structure

It has steel drums or anti-wear cast iron and hardened spray metal

Tensile power from 6.5 and 5.5 to 1.5 mm

Order with variable number of drums

Drum and doze cooling water system

Rotating dose system

Technical Specifications

Electricity consumption of each drum: 25 amps

Production rate: 1 to 5 tons per shift according to output size

Dimensions: 1 meter wide, 5 to 20 meters long (based on the number of drums)

What should the buyers of wire industry machines pay attention to in order to prepare a quality product and appear powerful at the start of their business?

The machines of the wire industry, due to the use of wire and wire in the process of converting this primary material into fence netting or press netting, or gabion netting, mesh netting, barbed wire and wire tensioning, etc., the performance of all these machines is always influenced by the wire used If the buyers do not do proper research in getting a quality machine or are influenced by the low price of low quality machines, they will face many problems and fail in starting their business. Some points should be noted

1- The machines of the wire industry are the types of weaving machines that work correctly with an accuracy of less than 0.1 mm, and if the manufacturer of these machines does not use modern production equipment and CNC machines in the production process, the final product will surely fail. It will hurt the buyer

2- In the process of making machinery for the wire industry, the experience of the manufacturer is very important, because the more a company produces the same product in a larger circulation, the more quality products it produces with safer performance, and by buying from these companies, you You have used their experience, if not buying from a reliable and experienced company is subject to failure of the buyer in his business path and paying money to an inexperienced manufacturer will lead to paying for the adventure of that manufacturing company and from your expense to Experience will come and the buyer will gain nothing but failure

3- Paying attention to the purchase of machines that are compatible with raw materials in the country and researching the performance of the manufacturer's products in a practical way in the market and paying attention to the fact that only European machine manufacturers do not make quality structures and not paying attention to this Is the foreign device compatible with the domestic cable or not?

During the research and experience of more than a decade in the manufacture of wire industry machines, it should be stated that few imported machines have performed correctly with Iranian wire, even German, English, Turkish and Chinese machines, because these companies make their machines with the quality of the country's wire. self-adjusting and calibrating, if they always have problems with Iranian wire, because domestic wire does not have uniform annealing, and this has caused the very poor performance of foreign products inside the country, while Pars Baft Company, with more than 20,000 experience in manufacturing machines Now, wire industry has always tried to build machines that are compatible with raw materials inside the country, and currently, with more than 90% of domestic wire, it has shown an outstanding performance, so that we have prevented the import of such machines into the country.

4- Buyers of machines for wire industries should always pay attention to the fact that installation, training, and after-sales service are considered to be the most critical items in the purchase of the machine, and these items are only possible by purchasing from reputable and large companies, which are Mass produce the consumable parts of all your machines on the production line with CNC machines and benefit from the experience of the company's large support team in order to achieve your business goals, because you are at the beginning of a business that A great manufacturer will get you to your goals faster than a weak manufacturer.

5- Buying a device that is easy to use and takes less time to learn how to use it and consumes less electricity is one of the things that a reputable manufacturer brings you closer to these goals.

6- Try to buy the wire industry machine that produces the most amount of wire with the least amount of wire used, because in today's market, the higher the price, the more buyers will come to your final product, and you will win the competition.

Pars Baft company has been successful in consuming as little raw materials as possible and producing more production circulation due to the special design of the mold and mold card and the aerodynamics of the fabric mold of all its products, so that up to 5% of production with Pars Baft machines is more economical than all It is the most modern devices in the world and this honor was achieved only with a lot of experience and research and development

7- Buying from companies that you can count on in the development of your business until the final destination and that have a complete set of products so that you can use their experiences for your progress.

8- Buying machines that have low noise so that they can be set up in any place and are fully mechanical and have low cost maintenance for many years and are designed as modules and use precise industrial tools in their construction. It is possible that these things are only possible by purchasing from a company with a long history and experience, so that Pars Baft company has been able to design products that have all the above features during years of research and development in the manufacture of all kinds of machines. But a device should not be pneumatic or hydraulic until mechanical systems cannot be used. Because pneumatic systems are very noisy and quickly go out of adjustment and are considered cheap and low-quality machines and have very high depreciation, on the other hand, hydraulic systems are very slow and expensive and very low efficiency if Speed is vital in the process of wire industry machines

Danesh Banyan Pars Baft Kolestan Company, with more than a decade of activity in manufacturing all kinds of wire industry machines and manufacturing various industrial lines and accepting and being able to manufacture all kinds of special and hi-tech machines even for military and government projects and... more than 2000 units has launched a successful and active industry inside and outside the country, which owes its increasing success to God and the round-the-clock efforts of its R&D unit, which has always been in the pursuit of making machines up to date in the world's industry, and has set great goals towards The improvement of the quality level of the producers and artisans of the world follows, so that the products of this company have been exported all over the world, including Australia, Iraq, Oman, Georgia, Armenia, etc. and have been welcomed by the world.