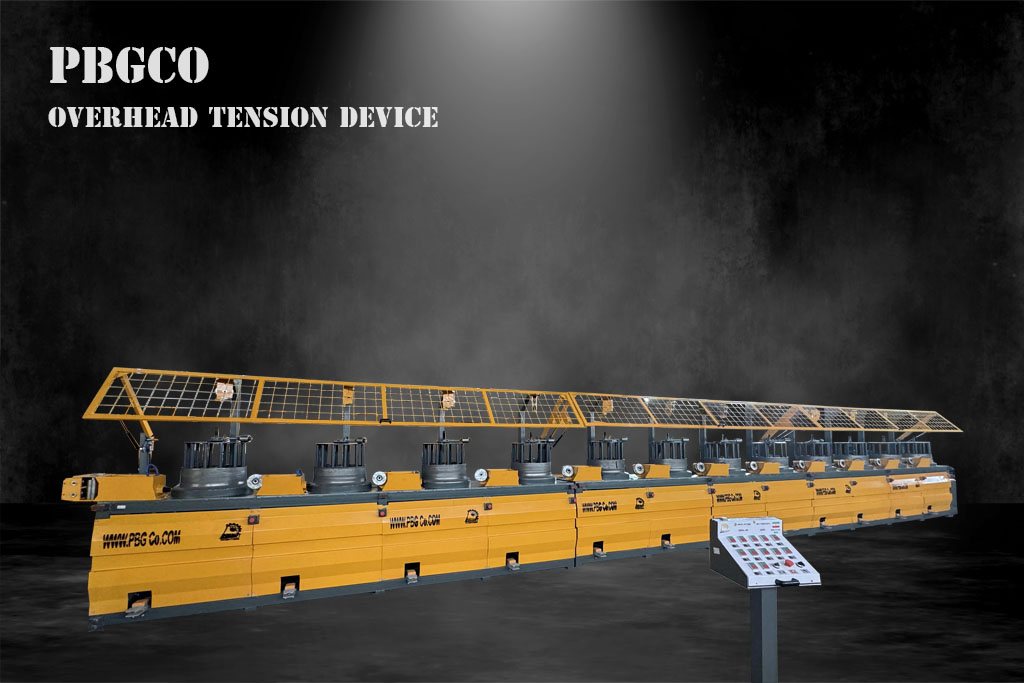

Overhead wire tensioning device

This machine transforms raw materials such as steel, aluminum, etc. into various shapes and sizes of wire by using tensile force.

The power and production capacity of the overhead wire tensioning machine from the Pass Baft set varies depending on the types and dimensions of the wire, as well as their production speed.

Pars Baft wire drawing machines (overhead and direct) usually have advanced control systems that allow them to adjust the speed and force to produce high quality wire.

In the operation of the overhead wire tensioning device from the pass weave collection, by using the tension force, the output product is very high quality and wire with your desired size. This process is done continuously and automatically and requires minimal human supervision and control.

Due to the wide importance of this device in various industries such as automotive, construction, electronics, etc., optimizing its performance and efficiency is of great importance. Improving the production process and controlling the quality of products produced using a wire drawing machine can help improve the performance and profitability of companies.

You can call for free consultation

09120172006

Call our experts to guide you.

The overhead wire tensioning device from the Pass Baft series usually has various facilities and capabilities that are used to optimize the performance and control the production process.

Some of the main facilities and capabilities of this device are :

- Advanced control system: The wire drawing machine usually has an advanced control system that allows the operator to monitor and precisely control the parameters of wire production. These systems can include adjusting speed, power, temperature and other parameters related to the production process.

- Electrical panel: Pars Baft wire tensioning machine has an electrical panel (no need for electrical room) which includes all the switches, contactors, relays and other electrical parts needed to control and run the device. In addition to electrical components, this unique switchboard also includes digital displays to display process parameters and production information. It should be noted that European traction devices are very advanced, equipped with an electrical room for ease of production and power supply to the device, but fortunately, the strong team of Pars Baft has been able to improve this problem by designing a unique electrical panel.

- Sensors and measuring devices: The overhead wire tensioning machine of the wire mesh pass series usually has various sensors and measuring devices that are used to measure sensitive parameters such as pressure, speed, temperature, etc. These devices provide the necessary information to the control system to optimize the production process.

And finally, it should be said that all the sensors and all the parameters of this device can be moved and even upgraded, and according to your order, budget and needs, this device is completely customized and produced exclusively for you.

- Options : depending on the type and application of the device, different options are considered for the wire tensioning device. Some common options include kneader, Torres kneader, coal kneader, powder kneader, glue kneader, etc.

By using these facilities and capabilities, the wire drawing machine will be able to produce high quality wire and optimize the production process.

The most important features of the wire tensioning device

easy usage

Designed for

Three shifts

All the company's products have a 1 -year warranty and 10 -year after-sales service, along with free installation and training throughout the country.

The most important points that buyers of overhead wire tensioning device should keep in mind when buying this product:

- Wire industry machines are tools used for weaving. These machines work correctly with very high precision, less than 0.1 mm.

- To produce quality and acceptable products, the manufacturer of these machines must use modern production equipment as well as CNC machines in the production process. Otherwise, the final product may cause dissatisfaction to the buyer.

- In the stages of manufacturing machines, the experience of the manufacturer is very important. Also, the use of modern production equipment and CNC machines play an important role in improving the quality and accuracy of products.

- Otherwise, the buyer may encounter ineffective and inappropriate products, which not only brings him dissatisfaction, but may also cause the loss of business opportunities.

- Therefore, in choosing wire industry machinery, one should pay attention to the technical aspects and experience of the manufacturer and consider modern and high-quality equipment .

- When buying machinery, we must pay attention to its compatibility with domestic raw materials. Also, research on the performance of the manufacturer's products is also important and can help in making the right choice. Only European manufacturers do not make quality machines and other factors should be taken into account.

- Also, paying attention to the compatibility of the external device with the internal wire is a vital point. Research in the wire industry machinery industry shows that imported machines do not perform better than Iranian wire.

This may be due to the non-uniformity of the country's domestic wire and the weakness in its annealing, which has a direct effect on the performance of foreign machines inside the country. The reason for the poor quality of domestic wire can be due to the non-adjustment and calibration of foreign machines with Iranian wire. However, Pars Baft company, with the experience of more than 2000 wire industry machines, has always tried to adapt to the quality of domestic wire, and the result of this effort is the outstanding performance of the machines with domestic wire in the country. This point actually caused us to stop importing this type of machines to the country.

- When you think about buying wire industry machines, you should pay attention to a very important point. The presence of installation, training, and after-sales service is among the critical items in the process of purchasing the device.

These items can only be provided by reputable and large companies, because they produce their machinery consumables in bulk using CNC machines and with their strong support team, they enable you to achieve your business goals. Since you are in the beginning stages of your business, choosing a great manufacturer will help you to reach your goals quickly, in contrast to choosing a weak manufacturer, you may not reach your goals and face failure by buying his products.

- By choosing a reliable manufacturer, you can buy a device for wire industry that guarantees easy use and quick training in working with it, and also consumes less electricity. These things will help you to get closer to your goals. Try to buy a machine for wire industries that produces the most amount of wire using the least amount of wire. In today's market, the cost price of the product is very important and buyers will be more attracted to your product if the cost price is more appropriate. As a result, in the competition with other competitors, you will be a brilliant winner. Pars Fabric Company has been successful in consuming as little raw materials as possible and producing more circulation due to the special design in the form of aerodynamics of the fabric mold of all its products. Up to 5% of production with Pars Baft machines is more cost-effective than all modern machines in the world, and this honor was achieved only with a lot of experience and research and development.

-

- Buying from companies that you can count on until the end of your business development and that have a set of standards required for complete products.

- Pars Baft knowledge-based company uses global and international standards for its activities, for example, the standards of the member of the International Organization for Standardization (ISO), which represents the International Organization for Standardization, are used.

The ISO organization is formed by the representatives of national standardization institutions and works in the field of developing international standards.

The goal of this organization is to integrate all the processes and routines of doing things according to the demands and legal conditions of all countries. Considering that Pars Baft company supports global and international standards, its activities and processes are at the level of national and international standards. - Possession of patent certificates that with innovation and creativity compared to previous examples in the whole world, you can be the right judge in choosing a company (knowledge base) to buy the machines you need.

- To buy a machine that makes little noise and can be set up anywhere, as well as being completely mechanical and requiring little maintenance over many years, it is better to buy from a company with history and experience.

These conditions are mostly provided by Pars Baft company, because it has been working in the field of machinery research and development for many years and has designed products with all the desired features.

Also, the use of precise industrial tools in the construction of machines is also considered. Also, note that the device should not be of pneumatic or hydraulic type, because pneumatic systems are accompanied by a lot of noise and quickly go out of adjustment.

These systems often represent cheap and low-quality machinery, as well as high energy consumption and maintenance costs. Therefore, tend to use mechanical systems.

With more than a decade of activity in the wire industry and the production of machinery, Danesh Banyan Pars Baft Golestan Company is definitely familiar with the problems and limitations of hydraulic systems.

Considering the importance of speed in the process of wire industry machinery, this company tends to use mechanical and electrical systems.

With continuous research and development and round-the-clock performance of its R&D team, Pars Buffet Company has been able to apply the latest and new standards of the world industry in the design and manufacture of its machines.

The successful activities and establishment of more than 2000 industrial units inside and outside the country, including military and government projects, show the ability and experience of this company in producing special and quality machinery.

Due to their high quality and global acceptance, Pars Woven products are sent to international markets and are sold in countries such as Australia, Iraq, Oman, Georgia, Armenia, etc. These products are highly appreciated by global buyers.