Automatic welding electrode production machine

Automatic welding electrode production machine |

Made in Iran ( Pars Baft Golestan ) with state-of-the-art technology

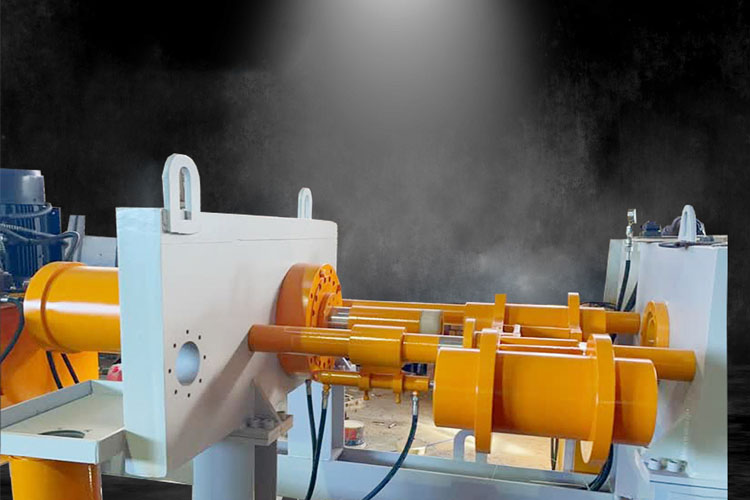

The automatic welding electrode production machine is one of the advanced products of the knowledge-based Pars Baft Golestan Company , which is designed and manufactured using the most up-to-date technologies in the world. This machine has the ability to produce a variety of general, specialized and anti-wear welding electrodes and is an ideal option for setting up an electrode production line inside and outside the country.

Why choose Pars Baft electrode production machine?

Modern and localized technology

Full support for installation, training and after-sales service

Possibility of producing high-quality electrodes for domestic and export use

Compatible with all types of welding wire from 2.5 to 4 mm in size

Save time and money with complete production line automation

Economic and industrial benefits of welding electrode production machine

Given the high consumption of welding electrodes in the construction, petrochemical, automotive, and energy transmission industries, investing in this production line is one of the most profitable options for entrepreneurs and industrial investors. Also, the export market for this product in neighboring countries and Central Asia is very hot and in high demand.

To receive free advice on setting up a production line, you can contact our sales experts right now:

📞 09120172006

📞 09120172008

The electrode production process in this device

Extruding and coating the welding mud

using a high-precision hydraulic extruder, the welding mud coating is applied to the metal wire.Brushing and sanding

to smooth and even out the electrode surface and remove impurities.Installing brand labels and technical specifications

including logo, standards and electrode information.Drying in a gas oven

with precise dehumidification to increase the durability and shelf life of the product.Final packaging and vacuuming

to maintain quality during storage and shipping.

Technical specifications of the device

| Feature | Specifications |

|---|---|

| Electricity consumption | 3 Phase – 32 Amps |

| Dimensions of the space required | 5 meters × 20 meters |

| Input wire size | 2.5 to 4 mm |

| Welding wire length | 30 to 45 cm |

| Machine weight | About 3.5 tons |

Outstanding technical features of the device

✅ Production of general and specialized electrodes

✅ Remote control system for speed adjustment

✅ High-precision magnetic feeder

✅ Precision transfer conveyor

✅ Automatic brush and sander

✅ Digital labeler

✅ Industrial gas drying oven

✅ Welding mud coating material mixer

✅ Electrode branching machine

Our experience and expertise are your quality guarantee.

Pars Baft Company, with more than ten years of specialized experience in designing and manufacturing wire industry machinery , is ready to provide consulting services, design, and manufacturing of various industrial devices to domestic and foreign customers.

📩 If you are looking to start a profitable business in the field of welding electrode production, complete the consultation form or contact us so that our experts will contact you as soon as possible.

Consulting and purchasing the device

If you are looking to increase productivity in the production of bed rebar, improve the safety level of construction projects, and update your production line, contact our consultants now.

📍 Golestan Province, Aqqala Industrial Park, End of Industry 1

📞 Direct contact number:

The most important points that buyers of electrode devices should keep in mind when purchasing this product:

The performance of wire industry machines is always affected by the quality of the wire fed to them. Therefore, if buyers do not do proper research in purchasing a quality machine or are influenced by the low price of poor quality machines, they