wire tension

Hello and courtesy, I am engineer Javad Rostami, a content production expert from Pars Baft Golestan company. I hope you enjoy this article.

wire tension

Introduction: Wire drawing is one of the main processes in the metalworking industry, where metal wires are subjected to tensile force to achieve desired sizes and dimensions. This process improves the mechanical properties of the wire, increasing its length and reducing its diameter. Wire drawing is used in the production of wires, cables, screws and various metal parts and plays an important role in various industries.

Wire tensioning methods: There are two main methods for wire tensioning: direct tensioning and ohde tensioning. Each of these methods has its own characteristics and uses.

1. Direct stretching: In this method, the wire is stretched directly without deviation. This method is mostly used in cases where we need high precision in sizes and reducing wire deviations. Direct drawing is used to produce precision wires and cables and can help reduce waste and increase productivity.

2. Ohad stretching: In this method, the wire is stretched through a series of wheels and rollers to reach the desired size and shape. Ohad tension is suitable for producing thicker wires and heavy industrial applications. This method is usually used when we need to make large changes in the shape and size of the wire.

Buying a wire tensioning machine: To perform the wire tensioning process, we need special tensioning devices. Wire tensioning devices are divided into two main categories: direct tensioning devices and overhead tensioning devices. Each of these devices has its own features and benefits.

1. Direct stretching device : These devices are designed to pull the wire directly without deviation and reduce its size and diameter. Direct drawing machines are very suitable for producing precise and thin wires and cables. These devices usually have advanced control systems for high accuracy and waste reduction.

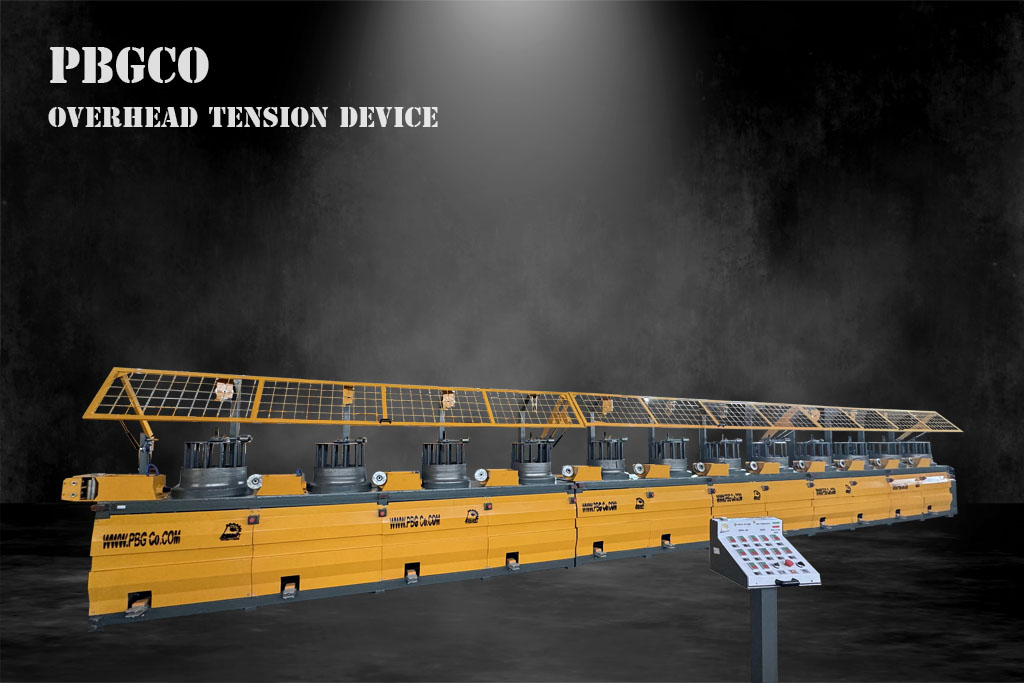

2. Ohad tension device: These devices bring the wire to the desired shape and size using wheels and rollers. Ohad drawing machines are used to produce thicker wires and heavy industrial applications. These devices have high flexibility and can make the wires into different shapes.

Pars Baft Company: Pars Baft Company, as the only manufacturer of wire tensioning devices in Iran, produces high quality devices in accordance with international standards. Using modern technology and expert teams, this company has designed its products to cover the needs of various industries. In addition to high quality, Pars Baft products also have competitive prices and good after-sales services.

Sources and content of semi-automatic wire tensioning machine

If you have any other questions or need more information, you can contact us through communication bridges or numbers

Contact the experts of the collection