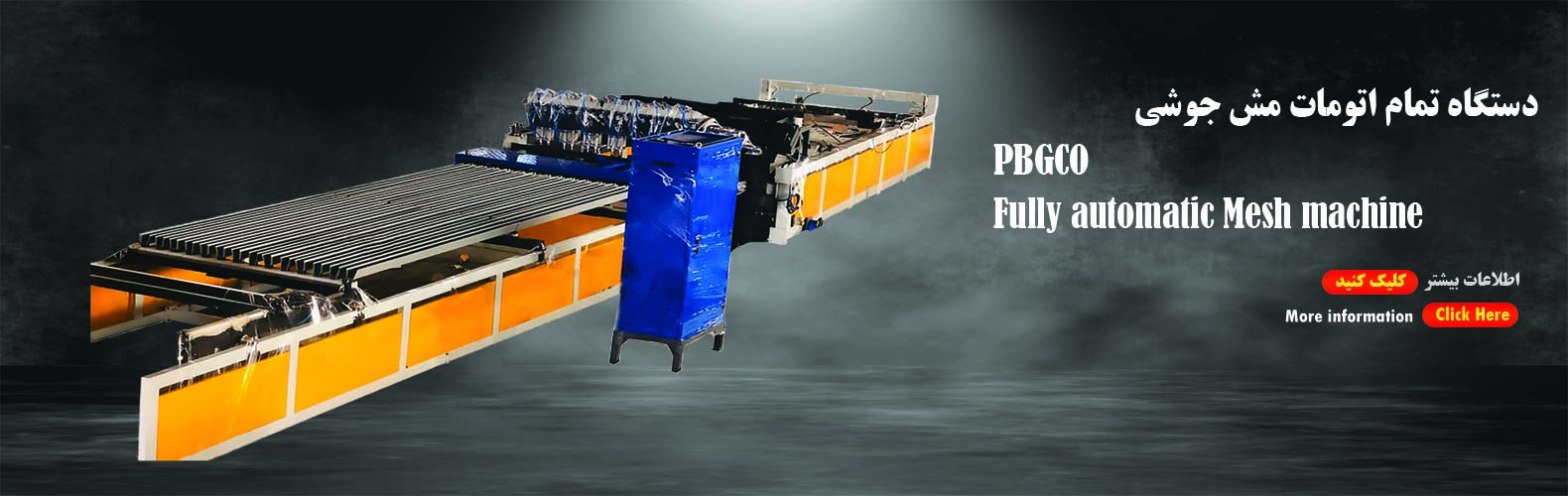

Welded mesh net production machine

Hello and courtesy, I am engineer Javad Rostami, a content production expert from Pars Woven Golestan Company. I am at your service to provide explanations about a new product about the fence weaving machine called {Mesh netting production machine}. I hope you enjoy this article.

Welded mesh net production machine

Welded mesh net production machine is a type of metal mesh production machine that is used to make metal nets using steel wire. This device is able to connect metal wires in the form of mesh screens or mesh panels.

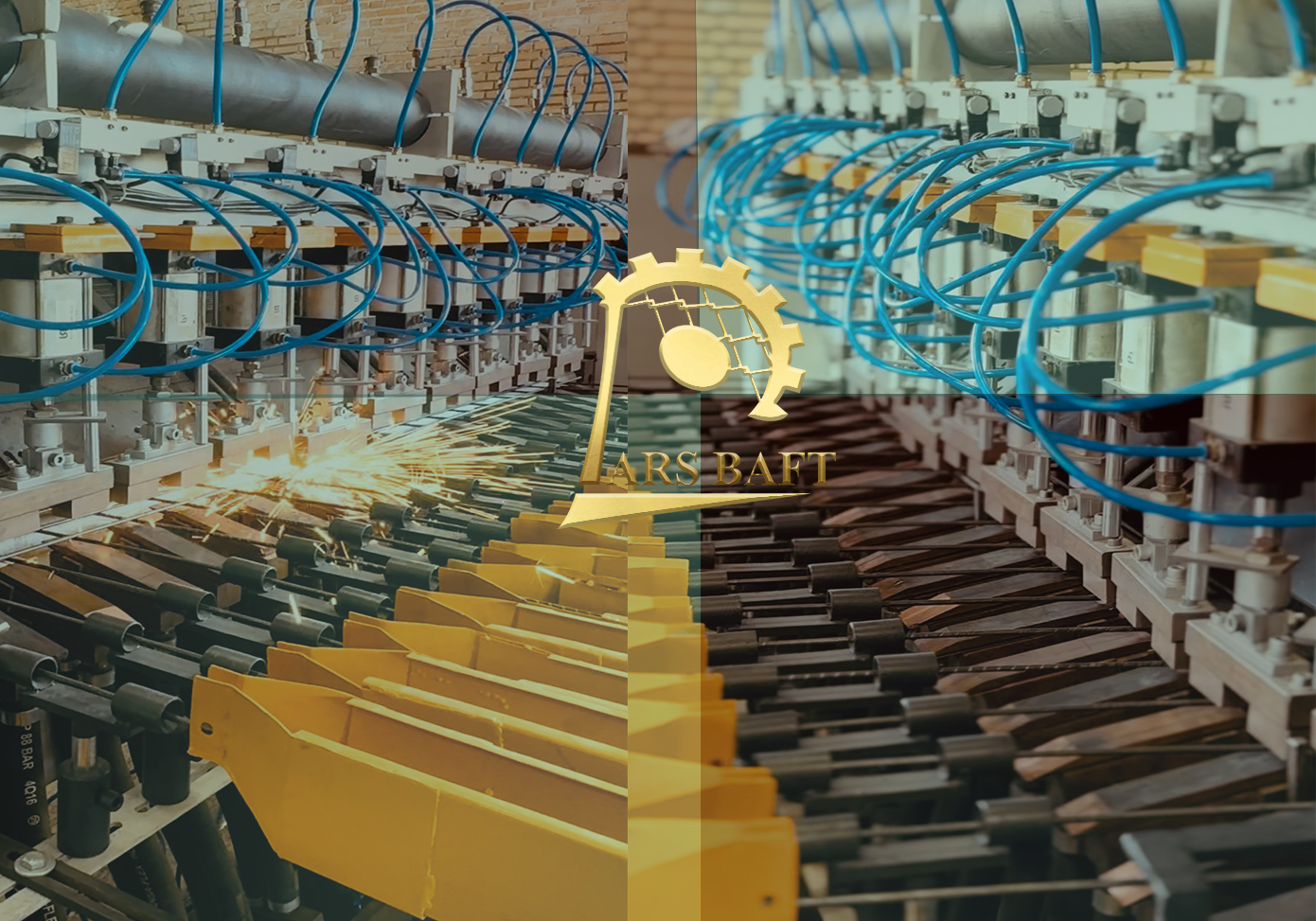

The welding mesh net production machine usually includes the following parts :

- Wire feeding system : This part provides metal wires and sends them continuously. Wires are placed horizontally and vertically in the device.

- Welding system : This section is used for welding wires. Electrodes and electric current generating devices are located in this part, which help to weld the metal wires and produce the mesh panel.

- Compression system : This part creates compression using mechanical components, so that the metal wires are connected and a net is formed. This compression is usually applied pneumatically or hydraulically.

- Control system and controller : This part controls the operation of the device and various parameters. The controller controls with the help of adjustable parameters such as wire flow speed, welding temperature and time, mesh thickness, etc.

Welded mesh net production machine is used to produce mesh nets, which are used to protect areas, buildings, industries and other types of uses. Using the welded mesh net production machine, different nets with different sizes, shapes and thicknesses can be produced depending on the desired requirements and specifications.

Types of welding mesh devices

Welding mesh devices are one of the important tools in the welding industry. These devices are used to connect metal parts using welding. Welded mesh technology makes it possible to create a large number of high quality and strong connections for industrial and construction applications.

One of the types of welding mesh devices is Mig/Meg device. This type of device uses the method of welding to a metal bubble that is limited by an electrode.

In this process, a metal wire wrapped by plating thick material is placed in front of the tension rack. Electric current passes through the wire and is transferred using shielding gas. These devices are very suitable for welding large parts and the limitations of working in large spaces.

The purpose of using this device is to improve thermal control in the welding process and create accurate and high-quality connections.

The device (laser welding) is also used in mesh welding. In this process, the laser beam is directed on the parts of the two metal pieces and causes them to melt at the point of contact.

The connection of parts obtained in this method has very narrow and precise connections with small distances and is suitable for welding electronic and sensitive parts.

Finally, the ultrasonic wave device is also used as a mesh welding device.

In this method, vibrating ultrasonic waves are produced in such a way that they cause friction between metal parts and cause heat generation and welding of parts. These devices are suitable for welding small and sensitive parts that cannot be welded by traditional methods.

Applications of mesh welding machine

The welding mesh machine is one of the important tools in the metal industry, which exposes metal parts to heat and pressure by welding. This device is used to create strong and safe connections in various industries and plays an important role in the production and manufacturing of industrial products.

One of the applications of mesh welding machine is in the automotive industry. In the manufacture and production of car parts, there are important connections between metal parts that must be very strong and reliable. Using a mesh welding machine, these parts are welded together and very strong and strong connections are made between them.

Welded mesh machine is also used in construction industry. In the construction of large and complex structures such as bridges, deep foundations and industrial buildings, many metal parts are used that must be welded together in a strong and safe way.

The welding mesh machine in this industry provides the possibility of making strong and reliable connections.

Aerospace industries also use mesh welding machine to weld metal parts. In the production and construction of aircraft parts, protection of metal joints against forces and harsh environmental conditions is very important.

To create strong and resistant connections, the welding mesh device is used as the main method.

Also, mesh welding machine is also used in oil and gas industries. In drilling and extracting oil and gas, the metal parts used are in very difficult and significant conditions.

By using the welding mesh device, the connections between metal parts and pipes are strengthened against pressure and harsh environmental conditions.

Features and advantages of the machine for producing welded mesh netting

The machine for producing welded mesh has the following features and advantages:

- High speed: the welding mesh net production machine is able to produce mesh net at high speed. This feature increases production capacity and reduces production time.

- Accuracy and precision: Using the welded mesh net production machine, nets with high precision and correct dimensions are produced. Accurate control parameters ensure optimal soldering and high strength.

- Adjustability: The welding mesh net production machine has the ability to adjust various parameters such as the thickness of the wire, the dimensions of the net cells, the type and number of wires. This feature allows the production of mesh nets with different dimensions and shapes.

- Strong connection: By using welded mesh welding, the connections between the metal wires are very strong and high strength. These connections are patched and integrated on the entire surface of the mesh net.

- Economical efficiency: using the welding mesh net production machine requires less cost and time to produce. Also, less manpower is needed for production operations and error factors are also reduced.

- High quality: The nets produced with the welded mesh netting machine have high quality and good strength. These nets can easily adapt to different loads, corrosion resistance and long life.

- Variety of applications: Welded mesh nets are used in a variety of applications due to their advantages such as strength, malleability and easy installation, including protection of areas, fencing, construction industry, construction, etc.

In general, the welding mesh net production machine with high efficiency, accuracy in production, adjustability and high quality is a suitable choice for the production of metal mesh net in all kinds of industries.

If you have any other questions or need more information about the welding mesh production machine, you can contact us through communication bridges or phone numbers.

Please get in touch