Fully automatic gabion machine

Greetings and courtesy. I am Javad Rostami, a content production expert from the pbgco team. I am at your service to provide explanations about a new fence weaving machine named {fully automatic gabion machine}. I hope you enjoy this article.

Introduction

The fully automatic gabion machine is one of the important tools in the construction industry. This machine is able to produce all parts of the gabion automatically without the need for manual intervention, using advanced technologies and also automating the production processes. In this article, we will review and explain the fully automatic gabion machine and its importance for We examine the construction industry.

What is gabion?

Gabion refers to an artificial structural system of steel or metal wires with a galvanized coating. This system is used to build beds, walls, separators and other structures in the field of buildings and civil engineering. Gabions give themselves significant resistance and strength by filling stones or other materials inside the wires. They are used for flood control, coastal protection, soil maintenance, as well as the construction of geysers and geyser walls.

What is a fully automatic gabion machine?

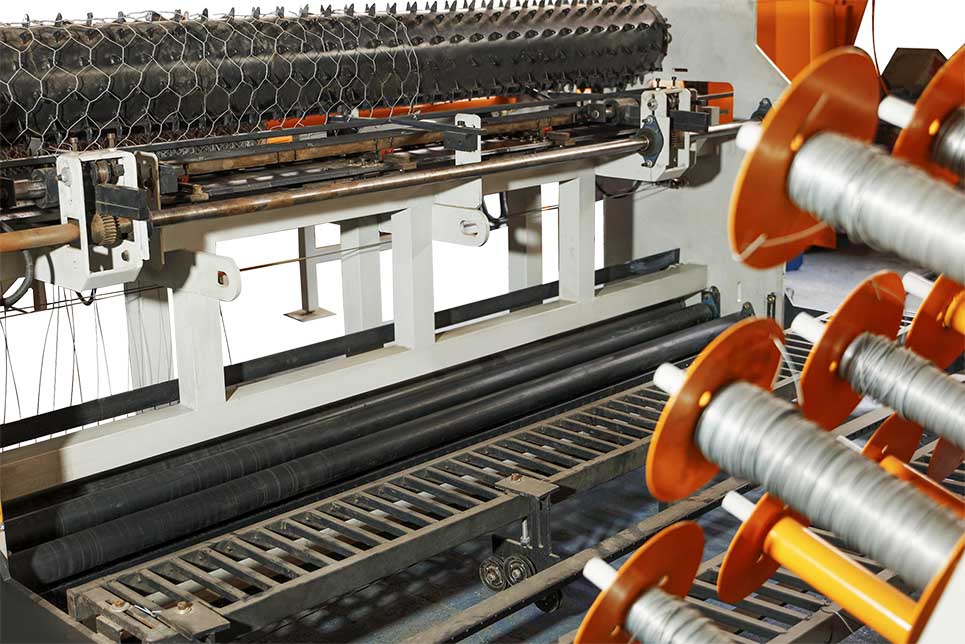

This machine performs a variety of tasks, including cutting steel wires to the required size, bending the wires into different shapes, welding the wires to connect the parts, and filling the gabion with stones or similar materials. These devices usually include advanced control systems and sensors. which perform the function of cutting, bending and welding automatically and with high precision. Some of the fully automatic gabion machines are also equipped with automatic systems for loading and unloading stones in the gabions. By using the fully automatic gabion machine, the production and construction of gabions is done faster, more accurately and with higher efficiency. The features and components of the fully automatic gabion machine All automatic gabion includes various components and features that help its automation and efficiency.

These components include:

1. Touch screen: This screen acts as a user interface for device settings.

2. Electronic control system: This system is responsible for controlling and coordinating production processes.

3. Pulping machine: This machine is used to produce metal wire with the required shape and diameter.

4. Cutting system: This system is used to cut the metal wire and create the required dimensions in gabion production.

How the fully automatic gabion device works The fully automatic gabion device performs the gabion production process automatically by using specified algorithms and settings. First, the metal wire required for making gabions is produced by a pulp machine, then the metal wire is cut to the required dimensions using a cutting system. Then the special forms in the machine are placed on the metal wire and the metal wire is automatically cut into the required shape. The opinion is bent. Finally, the manufacturing process is finished by injecting the raw material and packing the produced gabion. The advantages of using the fully automatic gabion machine The use of the fully automatic gabion machine has many advantages.

Some of these benefits are:

1. Increasing productivity: Using this device increases productivity and production speed.

2. Cost savings: Using the fully automatic gabion machine, production costs are significantly reduced.

3. Better quality: the fully automatic gabion machine produces gabion with higher quality and precision.

4. Reduction of errors: By automating the production process, human errors are minimized.

Applications of the fully automatic gabion device The fully automatic gabion device is used in various industries and sectors.

Some of the uses of this device are:

- Construction of protective walls: This device is used in the construction of protective walls in flood and storm areas.

- Pavement projects: using gabion in pavement helps to stabilize the soil and prevent surface erosion.

- Construction of roughness and lighting: Using gabion for construction of roughness and lighting in roads and public environments is common. Correct selection of the fully automatic gabion device. Various factors should be considered for the correct selection of the fully automatic gabion device.

- Some of these factors include production capacity, speed, and customization capabilities of the device. Before buying, you should carefully determine the needs and specifications of the project and compare them with the devices in the market. Future trends and developments in the fully automatic gabion machine In the field of fully automatic gabion machines, new developments are always happening. Some of the future trends and developments that may be observed in this field are: - Trying to improve the speed of the devices and increasing their efficiency by using intelligent systems and improving automation processes. - Paying attention to reducing production costs through optimizing processes, using From the optimal consumption of materials and higher productivity in production.- The use of virtual reality systems, computer vision systems and advanced algorithms to increase the accuracy in cutting, bending and welding of wires.- The use of energy-saving technologies and material recycling with the aim of reducing the effects Environmental.- The use of intelligent systems based on the Internet of Things (IoT) for better monitoring and control of production processes and faster troubleshooting. These developments and trends are aimed at improving performance, increasing quality and reducing costs in the production of fully automatic gabion devices. With the advancement of technology, it can be expected that the future of these devices will include new innovations and bigger developments. Conclusion The fully automatic gabion machine, using automation and advanced technologies, brings a significant improvement in the production of gabions.

- Some of the benefits include increased productivity, cost savings, better quality, and reduced errors. with A