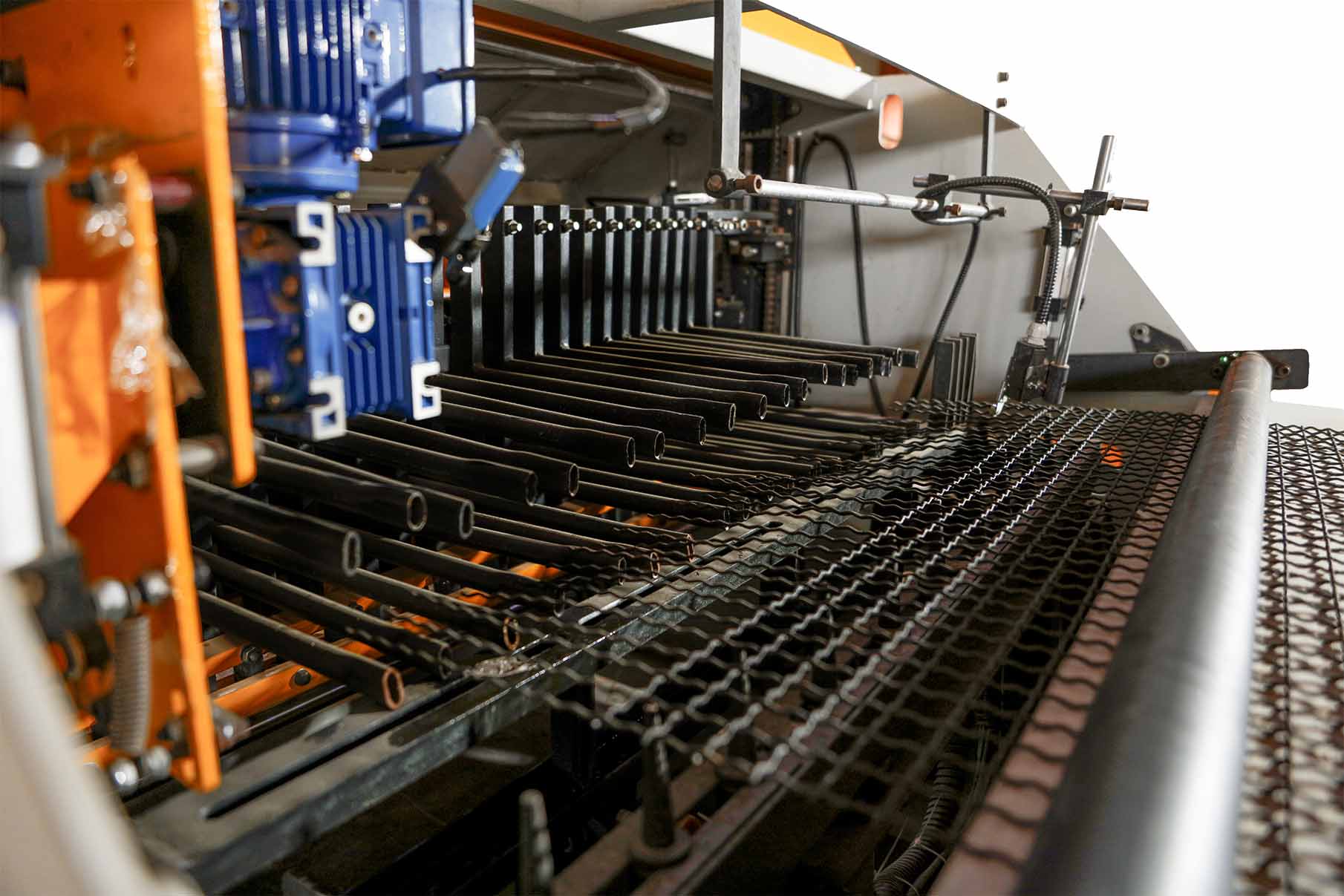

Fully automatic lace press machine

Hello and courtesy. I am Javad Rostami, a content production expert from the digital marketing team (pbgco). I hope you enjoy this article.

Press net production industry is one of the important metal industries that are used in many fields. Among the applications of these nets, we can mention construction, agriculture, as well as use in protective systems. Considering the importance of high-quality metal nets and the high demand for them, the use of a fully automatic net press machine is a suitable solution in production. These laces are introduced. In this article, we will examine the fully automatic press lace machine and its applications, and we will examine the features, working process, advantages and significant factors before purchasing this machine. Fully automatic press lace machine The full automatic press lace machine is an advanced equipment for producing high quality metal laces. Using modern technology and precise control systems, this machine works automatically and performs the lace production and packaging process quickly and without the need for manual intervention. The components of the fully automatic lace pressing machine The fully automatic lace pressing machine consists of various units that, in cooperation with them, carry out the lace production process. Some of the main components are: Wire winding unit: This unit is used to wind the metal wire into a net. Using automatic systems, the wire is wrapped with high precision and accuracy. Cutting unit: In this section, the wrapped laces are cut, depending on the required size and dimensions. Bending unit: This unit is used to bend the cut nets into the desired shape. Using different molds, laces are bent into various shapes and designs. Packing Unit: Finally, the quality metal nets produced are automatically packed. This packaging can include steps such as cutting, counting and final packaging. The cooperation of these components and intelligent systems will produce high quality metal nets automatically. Features of the fully automatic lace press machine The fully automatic press lace machine has many features and advantages, which include: High speed: using advanced systems, this machine is capable of producing various metal laces quickly and at high speed, which increases the efficiency of the line. high precision: by using an advanced control system, the fully automatic lace press machine is able to produce laces with precise dimensions and high quality, which leads to the improvement of the quality of manufactured products. Versatility: by changing the settings and formats, this The machine is able to produce laces of various dimensions and designs, and it allows customers to have wider choices. High efficiency: using a fully automatic press lace machine helps to achieve continuous and uninterrupted production. This increases productivity and reduces production costs. The working process of the fully automatic netting machine The working process of the fully automatic netting machine includes the following steps: Preparation stage: In this stage, the raw materials of netting, such as wire steel, arrive at the wire twisting unit. Wire steel is wrapped and prepared. Wire winding stage: In this stage, the wire winding unit wraps the wire in the form of a net using automatic systems. This process is done with high accuracy and precision. Cutting stage: After wrapping the net, it reaches the cutting stage. At this stage, the wrapped laces are cut to the required size and dimensions based on the programmed instruction. Bending stage: The cut laces then reach the bending unit. In this stage, the laces are bent using different molds to the desired shape and according to the customer's needs. Packing stage: In this stage, the produced quality metal laces are automatically packed. This step may include cutting the laces to the desired length, counting the number of laces and their final packaging. In each of the above steps, the fully automatic lace pressing machine uses accurate and intelligent control systems to perform the operation automatically and without the need for It does manual intervention. Sources and sources of the content of the fully automatic Tori Persi machine