Industrial screening machine

What is an industrial screening machine and how can it increase the productivity of screening mesh production? In this specialized article, we have examined common production challenges, technical criteria for selecting the machine, and a complete introduction to the Pars Baft Golestan screening machine in terms of engineering and application. A comprehensive guide for factory managers and industry activists for intelligent selection of production equipment. Author: Engineer Javad Rostami

Industrial screening machine; an engineering solution to increase accuracy, productivity, and reduce the cost of screen mesh production

Introduction

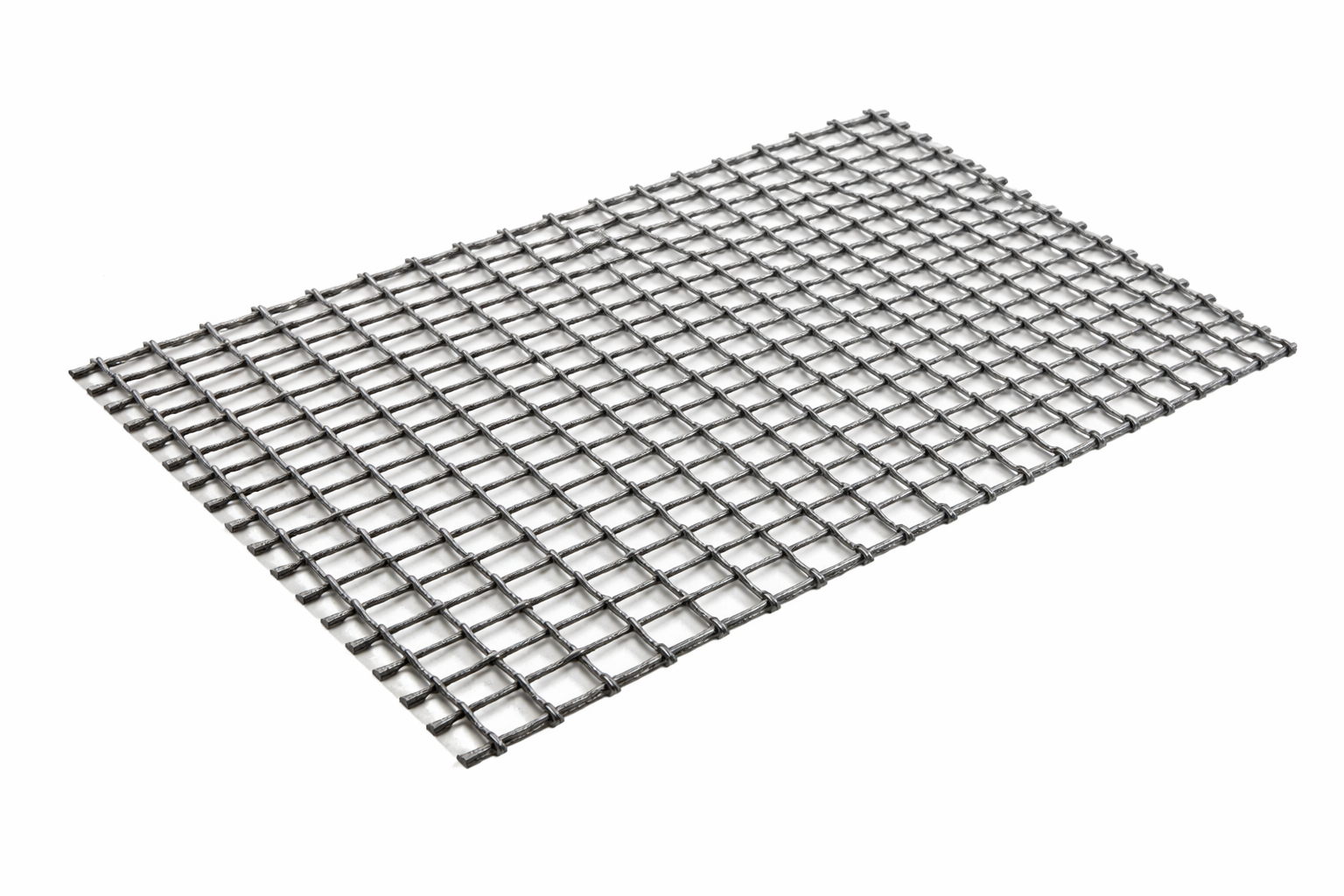

In many workshops and production units operating in the mining, construction industries, sand and gravel factories and civil engineering projects, the quality and uniformity of screen mesh plays a decisive role in the performance of the production line. However, screen mesh manufacturers often face challenges such as quality fluctuations, spring inconsistencies, raw material waste and frequent production line stops.

In the current market conditions and intense industrial competition, reducing waste, increasing production speed, and maintaining quality standards is no longer a competitive advantage, but a necessity. The solution to this problem lies not in sectional reforms, but in the use of standard and engineered industrial equipment such as an automatic screening machine; equipment that can upgrade the production of screening mesh from a workshop and semi-manual mode to an industrial and reliable level.

In this article, while carefully examining the needs of the industry, we will introduce the specialized screening machine produced by the Pars Baft Golestan Knowledge-Based Machinery Complex and analyze the technical criteria for its selection.

Investigating the main problem and need in the screen mesh production industry

As a key component of granulation and material separation systems, screen mesh must have completely uniform technical specifications. The slightest deviation in spring dimensions, wire tension, or weld strength can reduce the efficiency of the screening line and even damage the main equipment.

The most common problems in the production of screen mesh are:

-

Uneven spacing of springs in manual production

-

Weakness in the strength of joints or tissues

-

High wire consumption due to human error

-

Low production speed in semi-industrial methods

-

Strong dependence of quality on operator skill

Technically, these problems are often caused by the lack of a precise wire tension control system, the lack of an automatic gap adjustment mechanism, and the lack of precise alignment in the weaving or welding process. The direct result of these shortcomings will be increased waste, product returns from customers, and reduced market confidence.

Traditional or non-industrial methods and their disadvantages

In many small units, screen mesh production is still carried out using traditional methods or old mechanical devices. Although these methods appear to have a lower initial investment cost, they create significant hidden costs in the long run.

Common limitations of these methods include:

-

Low production speed and inability to respond to large orders

-

Human error in spring and tension adjustment

-

Lack of fine-tuning for various sizes

-

Inefficient energy consumption

-

High depreciation and frequent stops

From an economic perspective, reduced productivity increases the cost per square meter of screen mesh. In addition, inconsistent quality increases the risk of losing industrial contracts. In the B2B market, quality consistency is more important than price, and a manufacturer that cannot provide consistent quality will gradually be eliminated from the supply chain.

Industrial and standard solution in screen mesh production

The principled approach to industrial screen mesh production is based on three key principles:

-

Process automation

-

Precise control of technical parameters

-

Engineered design tailored to production capacity

A standard screening machine must have a wire tension control system, precise spring gap adjustment, complete coordination between the feeding unit and the weaving or welding unit, as well as a safety control system.

When selecting appropriate equipment, industrial managers should consider the following criteria:

-

Production capacity in line with sales plan

-

Ability to produce various fountain sizes

-

Durability of parts in heavy working conditions

-

Access to after-sales service

-

Possibility of customization based on project needs

Without considering these criteria, investing in equipment may result in increased maintenance costs and reduced productivity.

Introducing the Pars Baft Golestan Screening Machine

Pars Baft Golestan Knowledge-Based Machinery Complex, focusing on the design and manufacture of industrial equipment in the wire and mesh sector, has developed an automatic screening machine with an engineering and industrial approach.

This machine is designed to address common challenges faced by screen mesh manufacturers and enables uniform, fast, and accurate production of various screen meshes.

The role of the device in solving industry problems:

-

Reducing human error through automatic process control

-

Stabilizing the dimensions of the springs across the entire surface of the mesh

-

Increased production speed compared to traditional methods

-

Reducing wire waste and optimizing raw material consumption

-

Improving operator safety

The real competitive advantages of the device:

-

Precise control system for production parameters

-

Robust structure and vibration-resistant industrial design

-

Adjustable for different fountain sizes

-

Using high-quality, domestically sourced parts

-

Technical support and after-sales service by a specialized team

These features make the Pars Baft Golestan screening machine a reliable option for factory owners and production line managers.

To review more complete details and view the device's up-to-date specifications, it is recommended to visit the product page of the sieve device on the company's official website at pbg.co.ir. This link can be placed as an internal link in the product introduction section to strengthen the site's SEO structure.

Important technical specifications and factors affecting the selection of a screening machine

When choosing an industrial screening machine, it is very important to pay attention to the technical specifications. The most important parameters are:

Production capacity:

Production capacity should be determined based on the sales plan and annual orders. The machine should also be able to respond to possible increases in demand.

Energy consumption:

Optimizing the power transmission system and proper mechanical design plays an important role in reducing energy consumption. In conditions of increasing energy costs, this factor has a direct impact on reducing production costs.

The accuracy and output quality

of a standard machine must be able to maintain spring uniformity across the entire width and length of the net. This depends on the precise design of the wire guide system and tension control mechanism.

Customization Capability:

In many industrial projects, there is a need to produce mesh with specific specifications. The machine must be able to adjust parameters and produce a variety of sizes.

In addition, the quality of consumables, type of control system, and availability of spare parts also influence the final choice.

Important points before purchasing and setting up a screening machine

Before purchasing a screening machine, it is necessary to consider a few key issues:

The required space for

the machine dimensions and the side space for wire feeding and product collection must be carefully considered. Proper design of the production line layout prevents unwanted stops.

Manpower:

The level of automation of the machine determines the number of operators required. Proper operator training plays an important role in extending the life of the machine and maintaining quality.

After-sales service

Technical support, spare parts supply and access to expert advice are vital factors in long-term operation. Choosing a manufacturer that has a commitment to after-sales service reduces investment risk.

Carefully reviewing these items before purchasing will prevent unforeseen costs and facilitate the setup process.

Summary and conclusion

It is practically impossible to produce industrial screen mesh with uniform quality and high capacity without using a standard and engineered screen machine. Traditional methods, although they may seem inexpensive on the surface, in the long run lead to increased costs, decreased quality, and reduced competitiveness.

The screening machine produced by Pars Baft Golestan Knowledge-Based Machinery Complex, with a focus on automation, technical precision, and industrial durability, offers a practical solution for improving the productivity of screening mesh production lines. This machine can be considered as a strategic investment in expanding production capacity and stabilizing product quality.

To learn more about the complete specifications, images, available capacities, and receive expert advice, it is recommended to check the related product page on the official website of Pars Baft Golestan Complex at pbg.co.ir. This action can be the first step in optimizing the production line and increasing the profitability of your industrial unit.

The wire industry is one of the most attractive and profitable industrial sectors in the country today.

If you are planning to launch a production line

or are looking to upgrade your production capacity,

choosing the right machine is the most important step.

Pars Baft Golestan, the most complete manufacturer of wire industry machines in Iran

with patented equipment

and permanent support,

It is by your side.

📞 Call for consultation and price inquiry

Golestan Province, Aqqala Industrial Park, End of Industry 1

📞 Direct contact number:

⭐ Setting up a production line from zero to one hundred